News and information

newsThinkBus Lixin Mould (Hong Kong)Company Ltd

Attn.: YJ YANG

Email: yjyang@thinkbus.com.cn

Tel.: 151 1135 2731 (Wetchat & WhatsApp)

Add.: 15 Jianye 2nd Road, Shitanpu Industrial Area, Tangxia Town, Dongguan, Guangdong, China

Release time:21-06-09

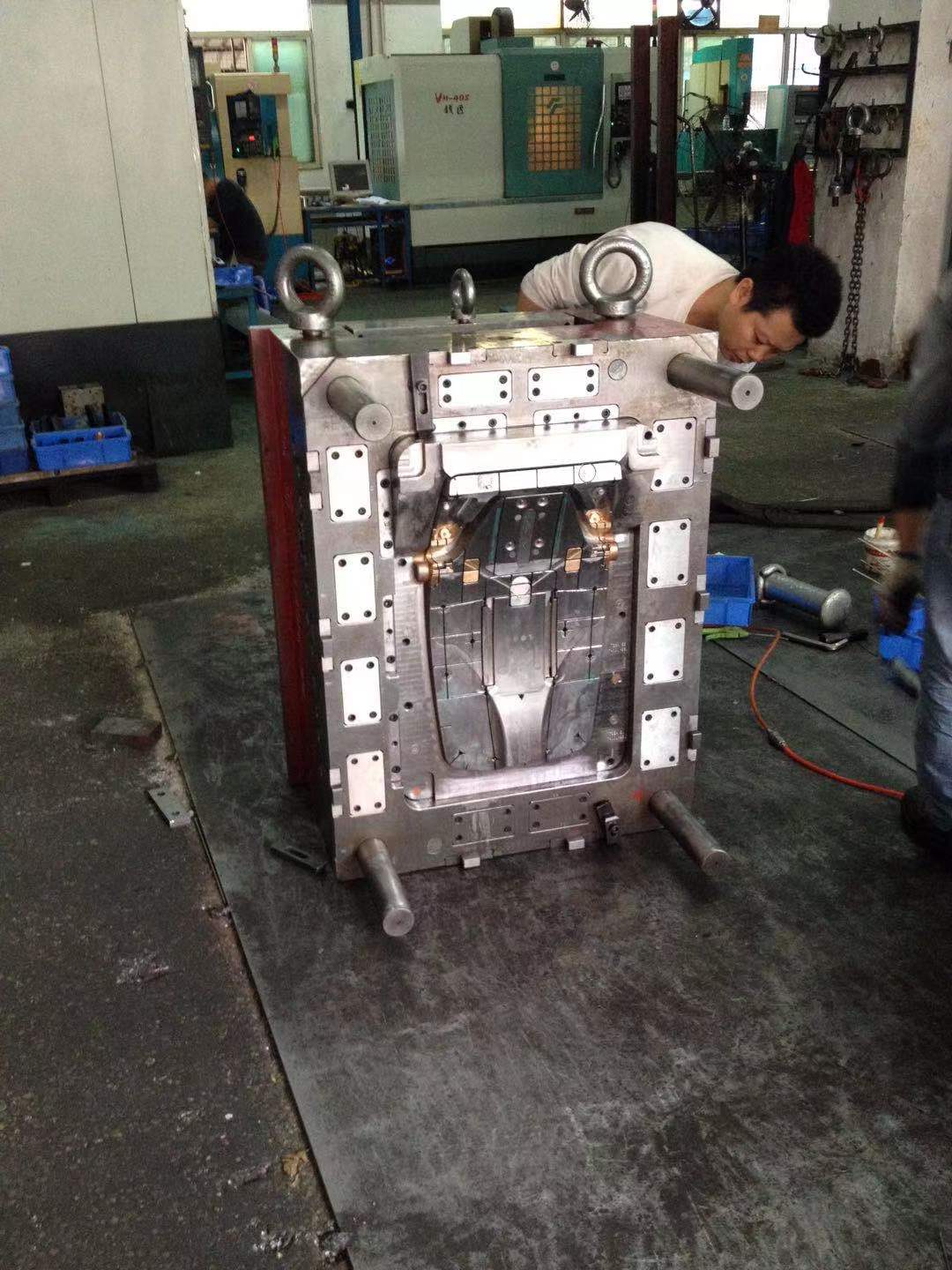

Mold is the main tool for product manufacturing and injection molding. Most of the molds adopt stamping casting or mixed die casting of various materials, such as rubber molding, ceramic molding, silica gel molding, etc. In the casting of these products, it is necessary to use vulcanizing agent at the high temperature of the equipment. After processing, some chemicals and release agents will remain in the mold. After a long time, the refractory glue carbon is formed after high temperature coking. How to clean the carbon mold? Next, follow Xiaobian to understand clearly.

Because the investment of injection mold is relatively large, so the daily maintenance of mold is very important. In the process of manufacturing plastic products, it is necessary to clean the mold regularly to avoid damaging the mold or affecting the production. In the case of rapid cleaning of deposits and plastic residues inside the mold; The traditional cleaning method is manual cleaning, easy to scratch the tolerance of the mold, time-consuming and laborious, the effect of cleaning the mold is not ideal.

With the rapid development of cleaning technology, dry ice cleaning mold technology has been widely used. Dry ice cleaning machine can clean the mold quickly and effectively with good cleaning effect, which can save cleaning time and reduce the number of dry ice particles sprayed on the surface of the mold to be cleaned by forced air. Through accelerated impact and physical low temperature effect, dry ice can make the dirt brittle and fall off, The mould dirt can be treated quickly; In the past, manual cleaning was very time-consuming. Due to the complex structure of the mold, manual cleaning in some areas was difficult, and it was unable to clean the complex position and the mold exhaust port. Dry ice cleaning machine can solve this problem, save cleaning time and make the mold simple.

Dry ice cleaning machine can clean the mold online without stopping, saving labor cost, simple operation, no mold wear, rapid mold cleaning, and the whole cleaning process can not produce secondary pollution, no impact on environmental sanitation, and no chemical agent. It is an environmental protection and drying cleaning method.